Product details of the zipper making machine

Product Specification

Warranty of core components: 1 Year

Marketing Type: Ordinary Product

Showroom Location: None

Applicable Industries: Garment Shops, Manufacturing Plant

Product Overview

zipper making machine is more cost-effective than other products in the same category. It is of reasonable structure, stable performance, and reliable quality. It has advantages such as low failure rate, low heat generation, low power consumption, high safety, and environmental protection. Our zipper making machine are as superb quality as well as the leading brand products. The long-lasting and stable performance makes this product a great advantage in the industry. zipper making machine is widely used to weld the following materials: automotive spare parts, metal spare parts, construction materials, stainless steel products, and others. ZYN Machine has customers and partners in many countries around the world.

Product Information

ZYN Machine adheres to the principle of 'details determine success or failure' and pays great attention to the details of zipper making machine.

Efficient Precision, Versatile Design

Enhance your production efficiency with our auto zipper machine, designed for seamless integration into your manufacturing line. The close-end injection molding machine guarantees precision and consistency in creating a variety of packaging shapes and styles, ensuring superior quality for your products. Experience the benefits of streamlined operations and reduced cycle times, giving you a competitive edge in today’s market.

● Precision

● Efficiency

● Durability

● Innovation

Efficient, precise, reliable, versatile

The innovative pressing plate location system ensures precise alignment during the molding process, which significantly reduces defects and enhances the quality of close-end items produced, particularly zippers.

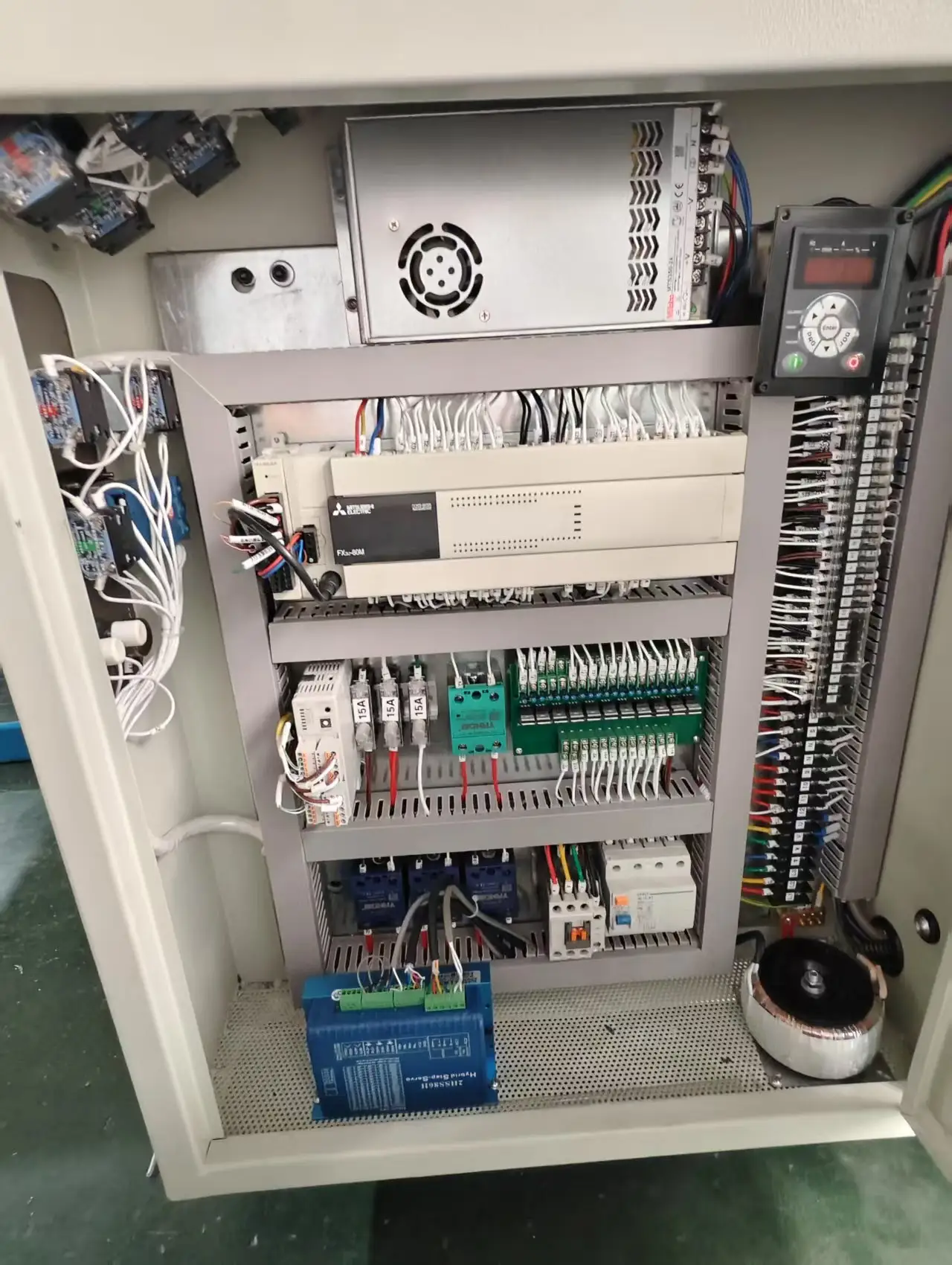

With advanced automation capabilities, the Auto Close-End Injection Molding Machine streamlines production processes, allowing for effortless operation and consistent output while minimizing the potential for human error.

The machine boasts fast cycle times, enabling manufacturers to meet high production demands without sacrificing quality. This efficiency leads to increased throughput and improved overall productivity.

Designed with energy efficiency in mind, this auto zipper machine reduces operational costs by consuming less energy and requiring minimal maintenance, making it a financially smart investment for modern production lines.

Precision Injection Molding Efficiency

The Auto Close-End Injection Molding Machine with Pressing Plate Location features advanced automation for efficient, high-quality production of close-end components, ensuring precise alignment and consistent results. Its robust design incorporates a specialized pressing plate mechanism that enhances operational stability and reduces cycle times, providing significant value in high-volume manufacturing environments. This innovative auto zipper machine not only streamlines the injection molding process but also optimizes energy consumption, ultimately delivering superior performance and reliability in the production of intricate mold designs.

◎ Precision

◎ Stability

◎ Reliability

The auto close-end injection molding machine with pressing plate location significantly streamlines the production of various types of bags. By ensuring accurate zipper placement, it enables manufacturers to produce high-quality, durable bags at a rapid pace, meeting the demands of both retail and industrial markets.

In the apparel industry, this integrated system allows for quick and efficient integration of zippers into garments. By automating the sealing process, manufacturers can enhance productivity and maintain quality standards, reducing the likelihood of defects while catering to fashion trends that require fast turnaround times.

The system is perfectly suited for creating a wide range of textile accessories that require zippers. Its precise operation ensures that zippers are securely and consistently applied, resulting in high-quality products such as pouches, cases, and other accessories that appeal to consumers seeking reliability and style.

In the footwear sector, the auto zipper machine plays a vital role in the efficient assembly of zippered shoes and boots. Its ability to seamlessly integrate with injection molding processes ensures that zippers are applied with precision, enhancing both functionality and aesthetic appeal while reducing labor costs in manufacturing workflows.

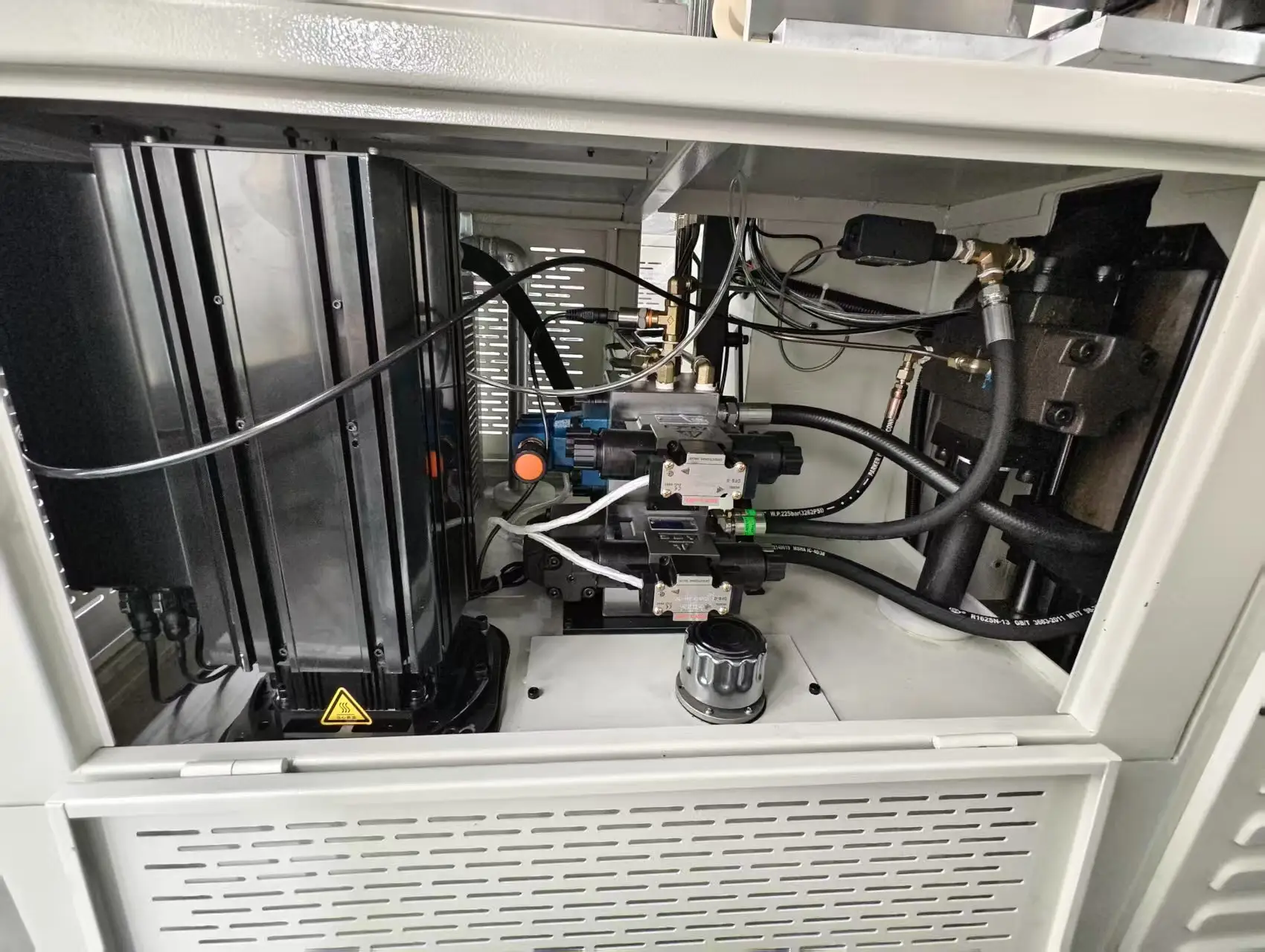

The auto zipper machine is crafted from high-quality materials designed to ensure durability and precision in the manufacturing process. Its close-end injection molding machine utilizes advanced polymers and robust alloys, enabling it to withstand the rigors of continuous operation while delivering exceptional performance. This careful selection of materials not only enhances the machine's reliability but also supports the production of consistent, high-quality zipper products.

◎ Durable

◎ Efficient

◎ Precise

1

What is an Auto Close-End Injection Molding Machine with Pressing Plate Location?

An Auto Close-End Injection Molding Machine with Pressing Plate Location is a type of injection molding machine equipped with a pressing plate location system that is designed to automatically close the mold during the injection process.

2

How does the pressing plate location system work on the Auto Close-End Injection Molding Machine?

The pressing plate location system on the Auto Close-End Injection Molding Machine is programmed to accurately position the pressing plate to ensure precise alignment and closure of the mold before the injection process starts.

3

What are the advantages of using an Auto Close-End Injection Molding Machine with Pressing Plate Location?

The main advantages of using an Auto Close-End Injection Molding Machine with Pressing Plate Location include improved product quality, increased production efficiency, and reduced cycle times.

4

Can the pressing plate location system be adjusted for different mold sizes?

Yes, the pressing plate location system on the Auto Close-End Injection Molding Machine can be adjusted to accommodate different mold sizes to ensure accurate alignment and closure during the injection process.

5

What are some common applications of an Auto Close-End Injection Molding Machine with Pressing Plate Location?

Auto Close-End Injection Molding Machines with Pressing Plate Location are commonly used in the manufacturing of precision plastic components, electronic parts, automotive parts, and medical devices.

6

How can I ensure the proper maintenance of an Auto Close-End Injection Molding Machine with Pressing Plate Location?

To ensure the proper maintenance of an Auto Close-End Injection Molding Machine with Pressing Plate Location, it is recommended to follow the manufacturer's instructions, perform regular inspections, and schedule routine maintenance checks by trained professionals.

Company Advantages

Wenzhou Hongye Precise Machinery Co., Ltd. plays a major part in the world market of zipper making machine. Wenzhou Hongye Precise Machinery Co., Ltd. has exceptional innovative manufacturing facilities. Under the guidance of strict management system, ZYN Machine always stick to the principle of customer first. Call now!

If you are interested in ZYN Machine's Zipper Machine,Zipper Teeth Making Machine,Zipper Slider Mounting Machine,Zipper Injection Moldin, please contact us quickly. We will always provide sincere service for you!