ZYN Machine-Precision And Innovation Zipper Machine Manufacturer Over 30 Years.

Quality Zipper Injection Molding Machine Zipper Injection Molding Machine Company

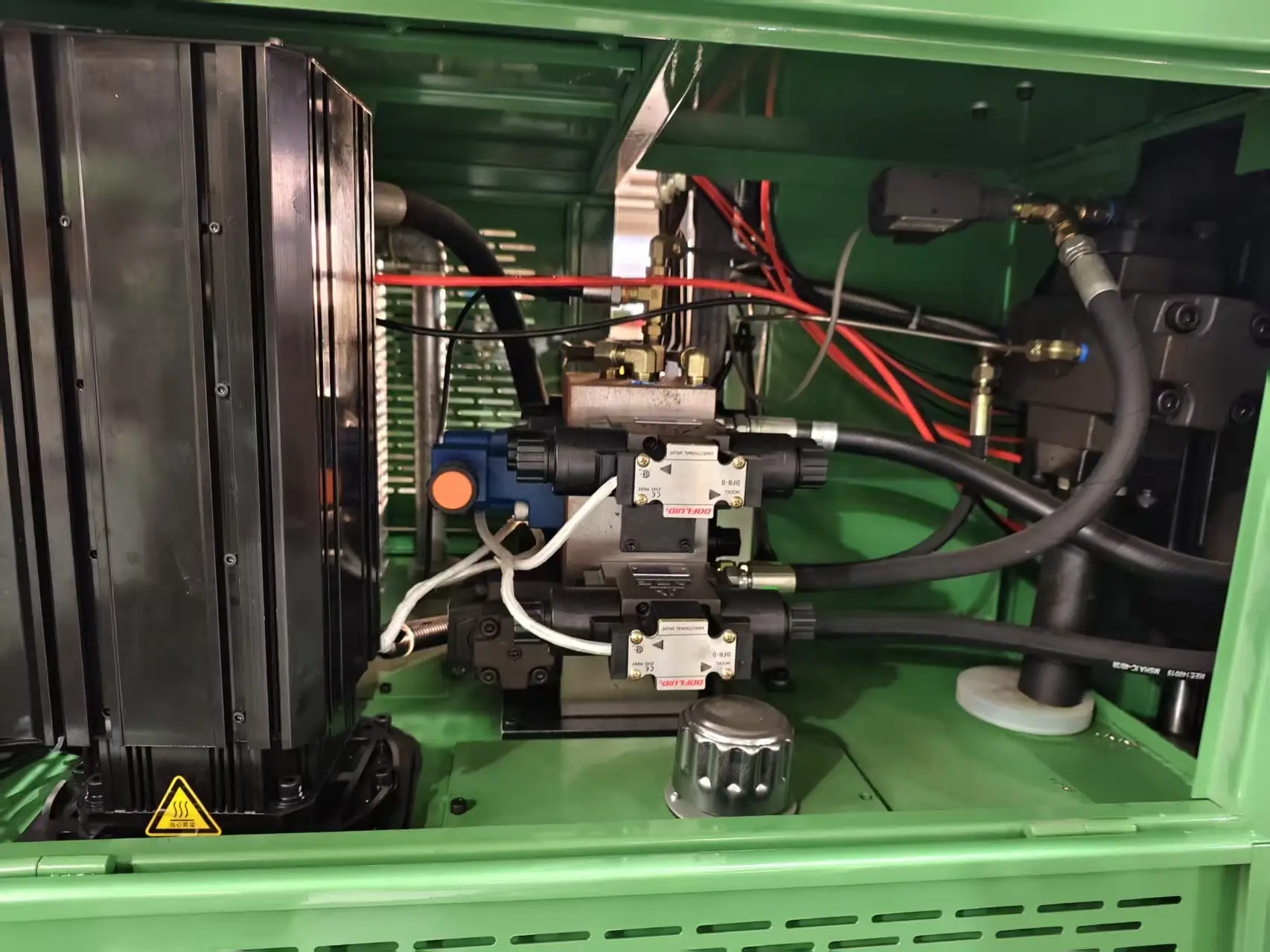

Product details of the zipper injection molding machine

Product Specification

Certification: CE

Power (kW): 6.5 KW

Dimension(L*W*H): 220*85*210 CM

Voltage: 380 V

Production Capacity (kg/h): 800-1100 PCS/60 CM/H

Product Overview

zipper injection molding machine is made of selected good materials and is manufactured based on advanced production technology. It is excellent in performance, high in quality, and long in service life. Now it is widely applied to the vacuum coating industry. Wenzhou Hongye Precise Machinery Co., Ltd. can customize the colors, shapes and sizes according to the needs of clients. Every piece of the product is strictly checked according to the international quality system. Excellent in performance and good in quality, zipper injection molding machine can meet the needs of cutting and deep processing for all types of metal tubes. The product plays an important role in the marketplace through a huge sales network.

Product Description

Next, ZYN Machine will present you with the specific details of zipper injection molding machine.

Efficient, Precise, Reliable, User-friendly

The HY-126S-A Automatic Open-End Injection Molding Machine with Special Top Stop Feature is a top-of-the-line auto zipper machine designed to enhance productivity and efficiency in zipper manufacturing. With its advanced technology and high-quality construction, this machine ensures precise and consistent results, making it an essential tool for any production facility. Upgrade your production line with this reliable open-end injection molding machine to streamline your operations and meet the demands of your customers.

Precision Top Stop Technology

The HY-126S-A Automatic Open-End Injection Molding Machine with Special Top Stop Feature is a high-performance auto zipper machine that offers precise and efficient production of open-end zippers. With its special top stop feature, this machine ensures accurate and consistent zipper closure every time, providing value for manufacturers in the textile industry. Its advanced product function attributes, coupled with a sturdy structure, make it a reliable and versatile solution for businesses seeking to streamline their zipper manufacturing process.

Innovative Top Stop Functionality

The HY-126S-A Automatic Open-End Injection Molding Machine is a top-of-the-line auto zipper machine with a special top stop feature. This advanced machine offers precise and efficient molding capabilities for open-end zippers. With its innovative design and high-quality performance, the HY-126S-A is the ideal choice for manufacturers looking to streamline their production process.

◎ Precision

◎ Automation

◎ Efficiency

Material introduction

The HY-126S-A Automatic Open-End Injection Molding Machine with Special Top Stop Feature is constructed using high-quality materials such as stainless steel and durable plastics to ensure longevity and reliability in operation. The robust design of this auto zipper machine allows for efficient production processes and consistent output of high-quality zipper products. Its special top stop feature adds an extra layer of precision and control, making this open-end injection molding machine a top choice for manufacturers in the garment and accessories industry.

Efficient, precise, innovative, convenient

The HY-126S-A Automatic Open-End Injection Molding Machine with Special Top Stop Feature is a cutting-edge auto zipper machine designed for seamless and efficient production. Its advanced technology allows for precise molding and seamless top stop integration, ensuring high quality end products. The machine's innovative features and exceptional performance make it a top choice for manufacturers in the industry.

◎ Precision

◎ Efficiency

◎ Reliability

FAQ

Company Information

Wenzhou Hongye Precise Machinery Co., Ltd. specializes in the production and processing of Zipper Machine,Zipper Teeth Making Machine,Zipper Slider Mounting Machine,Zipper Injection Moldin. The phenomenon of product homogenization is serious in the machinery industry. Therefore, ZYN Machine strives to make progress and seek development and innovation. And we established the brand called ZYN Machine, sticking to the development route of product differentiation. ZYN Machine is devoted to provides quality services to meet the needs of customers. ZYN Machine guarantees the high quality and timely delivery of products, based on multi automated production lines and scientific quality management system. And we are able to provide customers with professional and efficient custom services.

ZYN Machine's Zipper Machine,Zipper Teeth Making Machine,Zipper Slider Mounting Machine,Zipper Injection Moldin have multiple types and reliable quality. Customers from all walks of life are welcome to call us for consultation!