ZYN Machine-Precision And Innovation Zipper Machine Manufacturer Over 30 Years.

Product details of the zip lock bag making machine

Product Specification

Dimension(L*W*H): 200*72*215 CM

Power: 6.0 KW

Power (kW): 6.0

Production Capacity (kg/h): 1000 PCS/60 CM

Product Information

ZYN Machine zip lock bag making machine is produced using the lean production method. Our professional QC staff will strictly check the product to make sure that it is qualified enough to meet the international quality standard. The product is very popular in the industry especially for its unique features.

Efficient, Reliable, Precise, Durable

Our automatic open-end injection molding machine with an inject pin box is designed for efficient and precise zipper production. This high-quality machine guarantees superior performance and durability, making it a must-have for any manufacturing operation. Upgrade your production process with this reliable and advanced injection molding technology.

● Efficiency-driven

● Precision-focused

● Time-saving

● Reliable technology

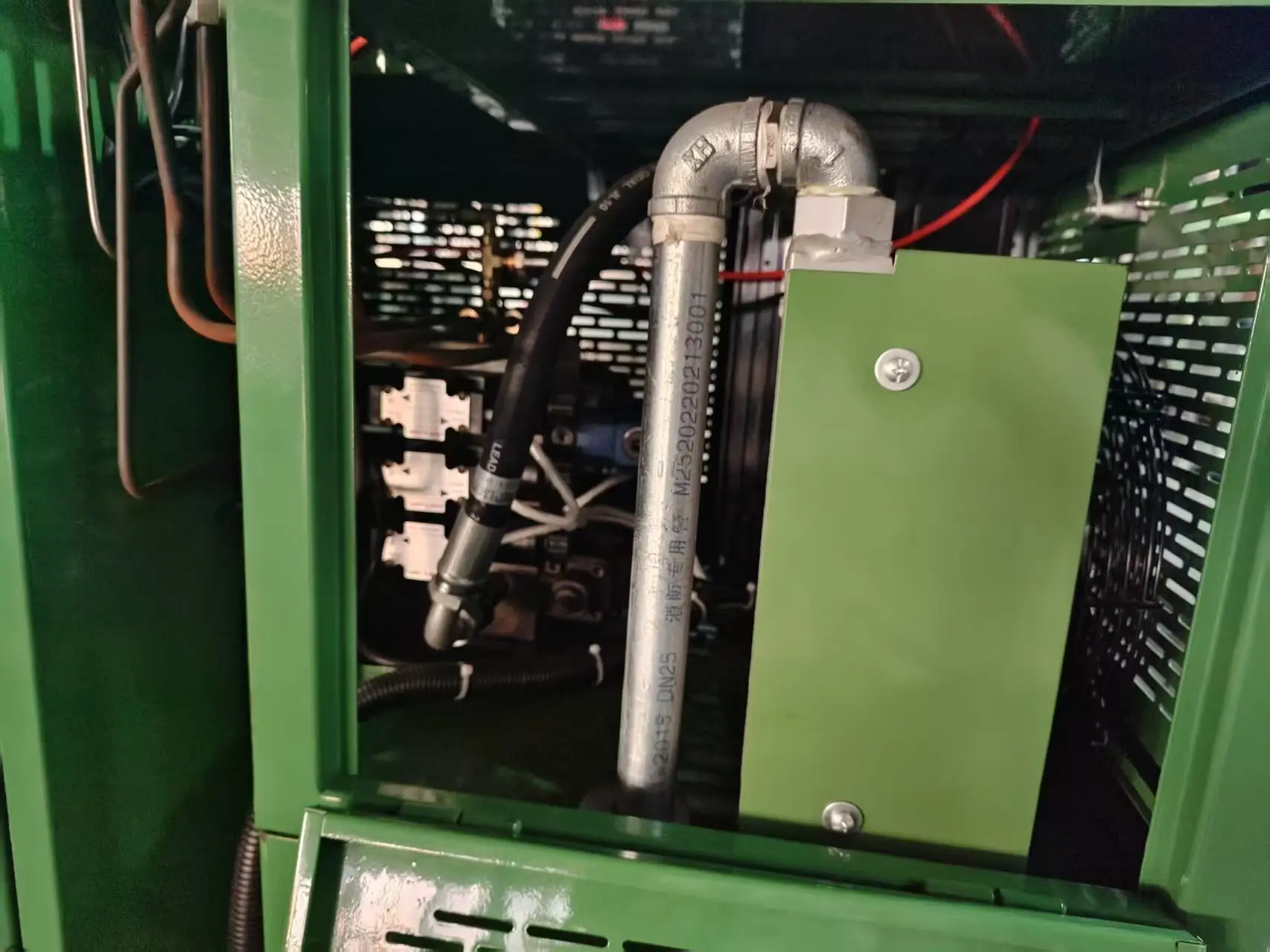

Product Display

Efficiency, Accuracy, Versatility, Speediness

Efficient, Precise, Automated, Reliable

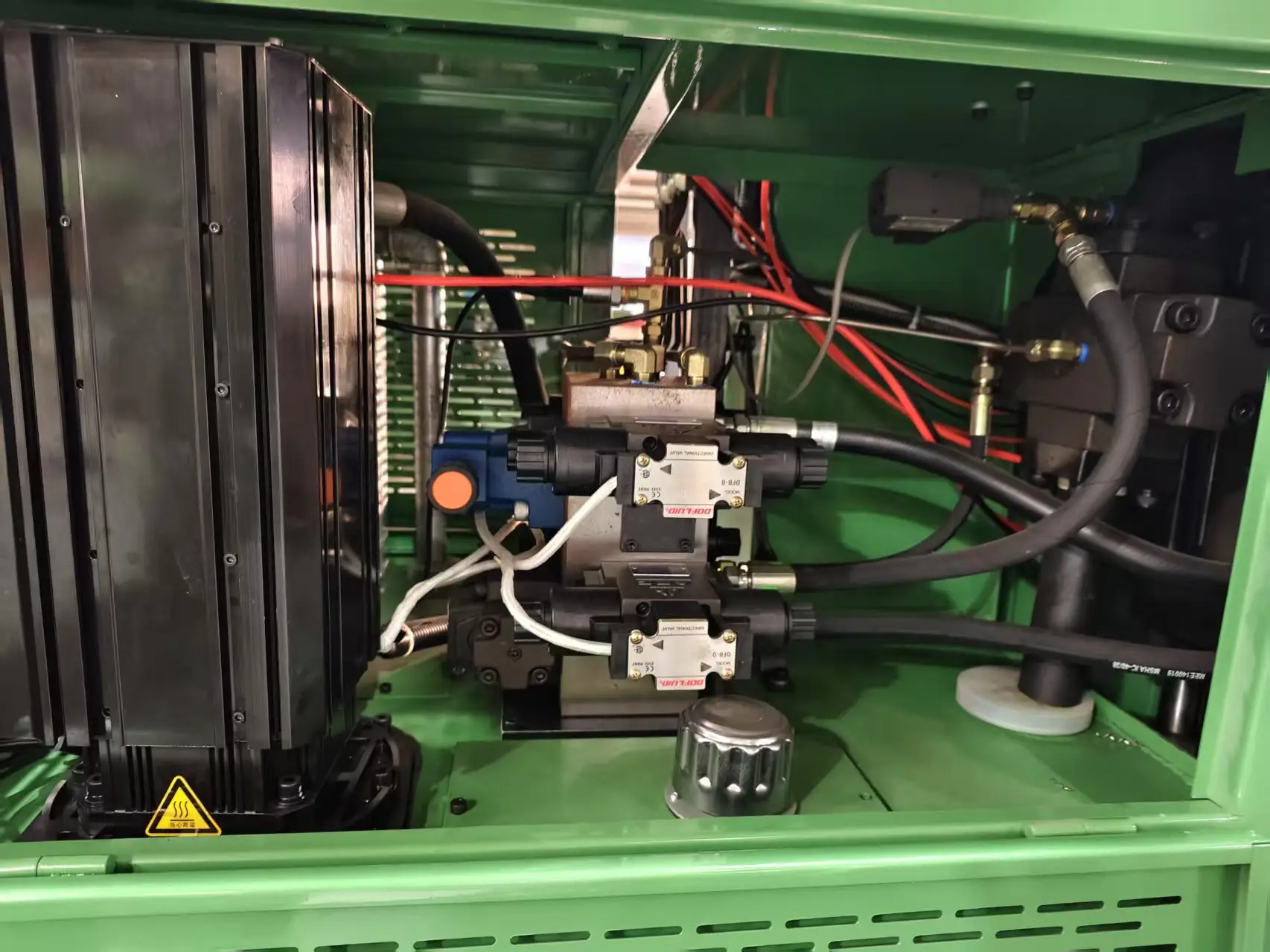

This high-quality auto open-end injection molding machine with inject pin box is designed for efficient production of zippers. Its core attributes include precision control and high productivity. With automatic features and a sturdy structure, this injection molding machine is a valuable asset for any manufacturing operation specializing in zipper production.

◎ Advanced Injection Technology

◎ Automatic Operation

◎ Durable Structure

Application Scenario

Material Introduction

The auto open-end injection molding machine with inject pin box is made of high-quality materials such as sturdy metal alloys for durability and resilience during the injection molding process. The automatic zipper machine's components are designed to withstand high pressure and heat to ensure efficient and precise molding results. With its robust construction, this machine delivers consistent performance and reliable operation for a wide range of injection molding applications.

◎ Steel

◎ Plastic

◎ Precision

FAQ

Company Feature

• ZYN Machine was founded in Having struggled hard for years, we are now a machinery manufacturer with certain industry influence.

• ZYN Machine is located at the intersection of different highways with great geographic position and easy traffic. Based on that, the distribution of supply is convenient and it is the ideal place for the sustainable development of the enterprise.

• ZYN Machine takes a proactive approach to open up the domestic and international market. We also construct sales channels according to the product's market positioning.

• ZYN Machine has a core R&D team composed of senior technical talents with strong professional capabilities, which provides a strong guarantee for product development.

• Our company carries out standard production based on the advanced production equipment and a full set of quality inspection equipment. With the guarantee of reliable product quality, sufficient supply and efficient delivery, we could provide customers with quality custom services.

We have ample inventory and discounts for large purchases. Welcome to contact us!