ZYN Machine-Precision And Innovation Zipper Machine Manufacturer Over 30 Years.

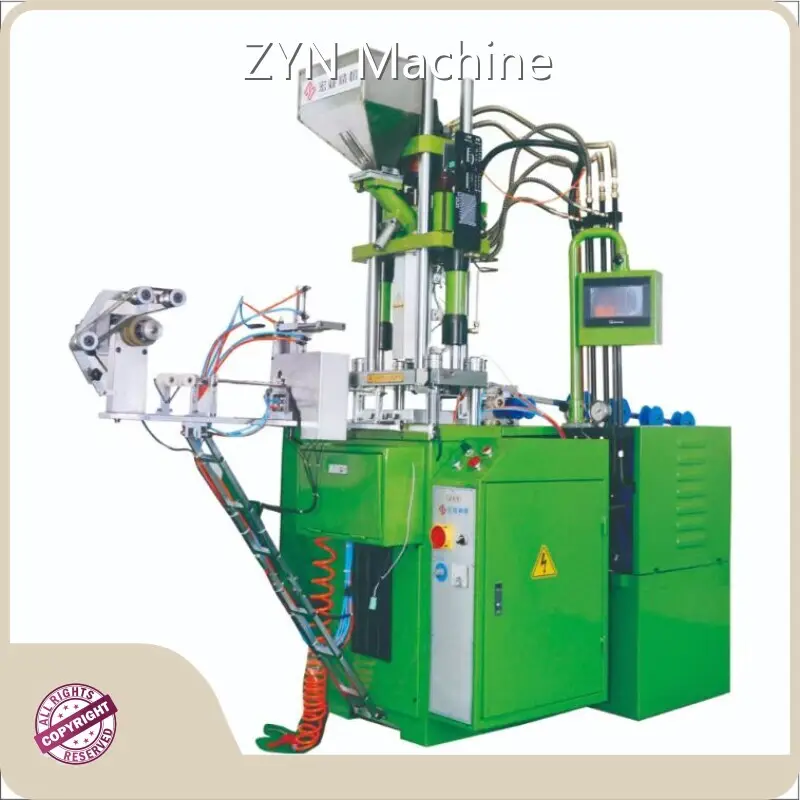

High Quality Zipper Making Machines

Product details of the zipper making machines

Product Specification

After salesService Provided: Engineers available to service machinery overseas

Dimension(L*W*H): 225*85*215 CM

Machinery Test Report: Provided

Condition: New

Warranty of core components: 1 Year

Product Overview

zipper making machines is an ideal equipment for industrial production. It has good exterior and compact structure. It is stable and reliable in performance as well as easy in operation. It also has advantages of high efficiency, low power consumption, high firmness, and long-lasting durability. zipper making machines is exquisite in craftsmanship. In our factory, we adopt the most stringent set of quality management system. zipper making machines is widely used for welding materials such as automotive spare parts, metal spare parts, construction materials, and stainless steel products. Wenzhou Hongye Precise Machinery Co., Ltd. is a customer-centric company.

Product Description

ZYN Machine's zipper making machines has superior quality. The specific details are presented in the following section.

Efficient, Precise, Versatile, Reliable

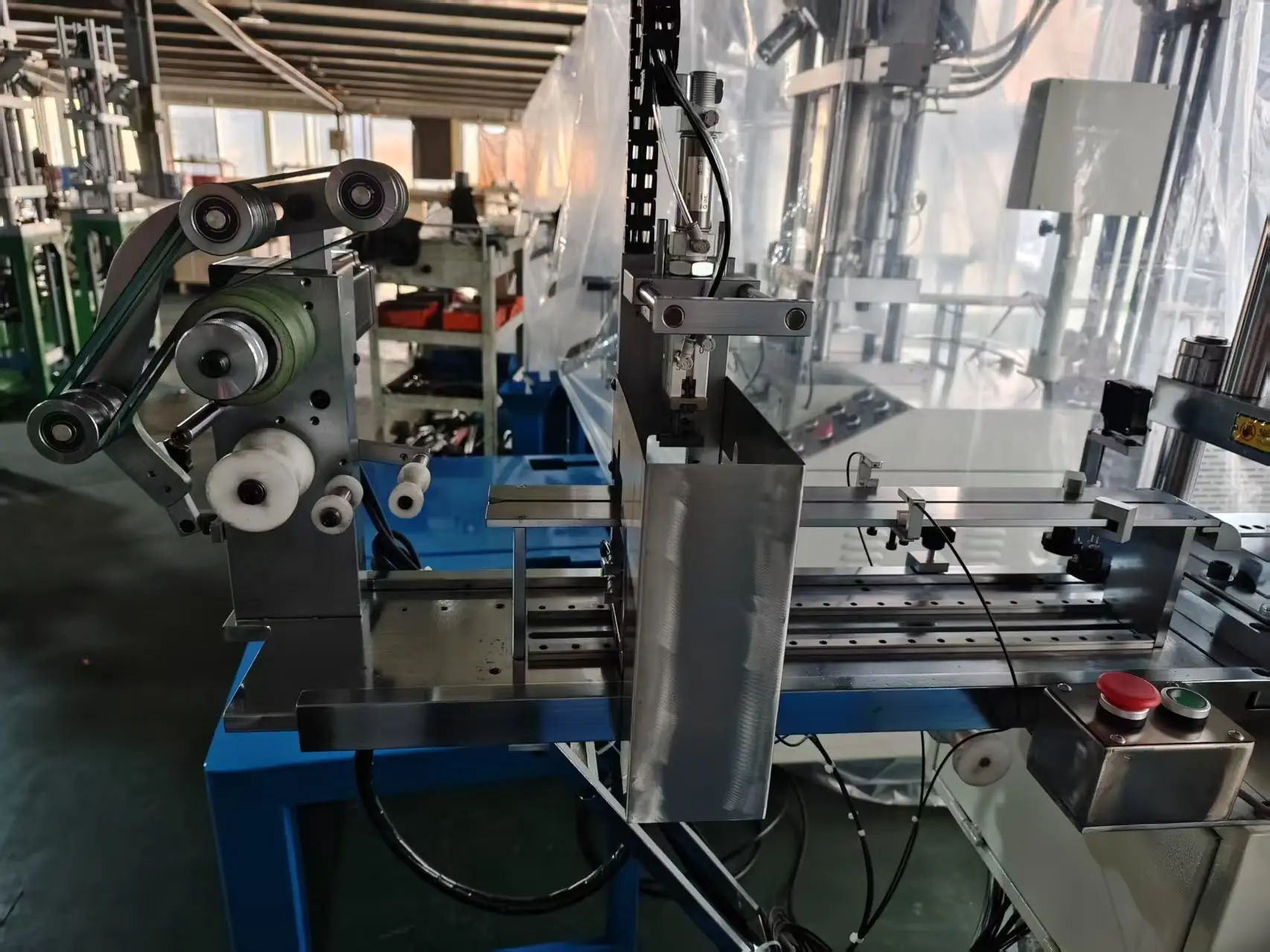

Experience unparalleled efficiency with our auto zipper machine, designed to seamlessly integrate with the close-end injection molding machine for precision production. This innovative system ensures consistent quality, allowing you to create custom shapes and stylish designs that meet your packaging needs. Enhance your operational workflow and achieve superior output with a machine engineered for reliability and excellence in the manufacturing process.

● Efficient Production

● Precision Engineering

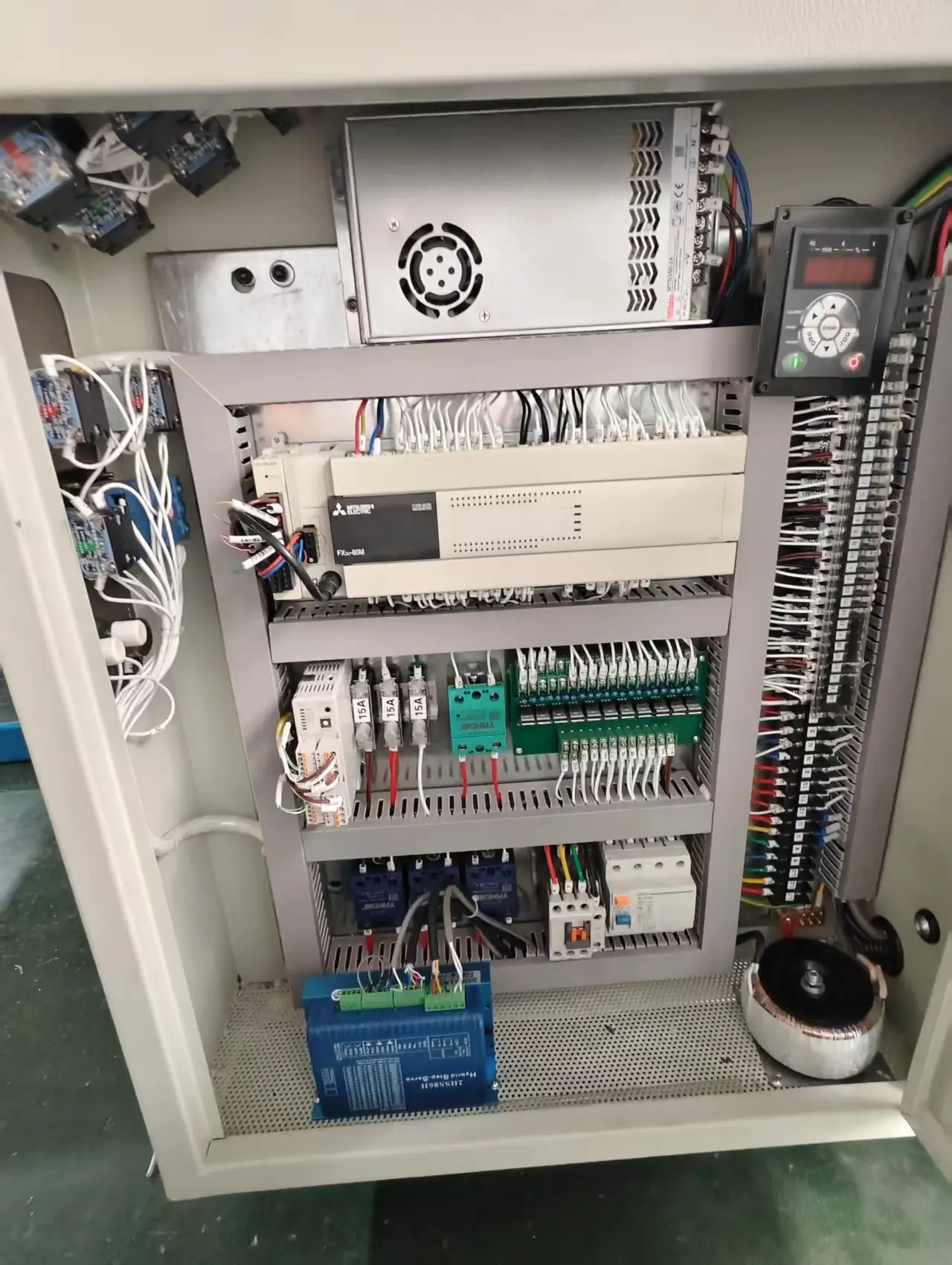

● User-Friendly Interface

● Durable Construction

Product Display

Efficient, Precise, Innovative, Reliable

Efficient, Precise, Automated, Reliable

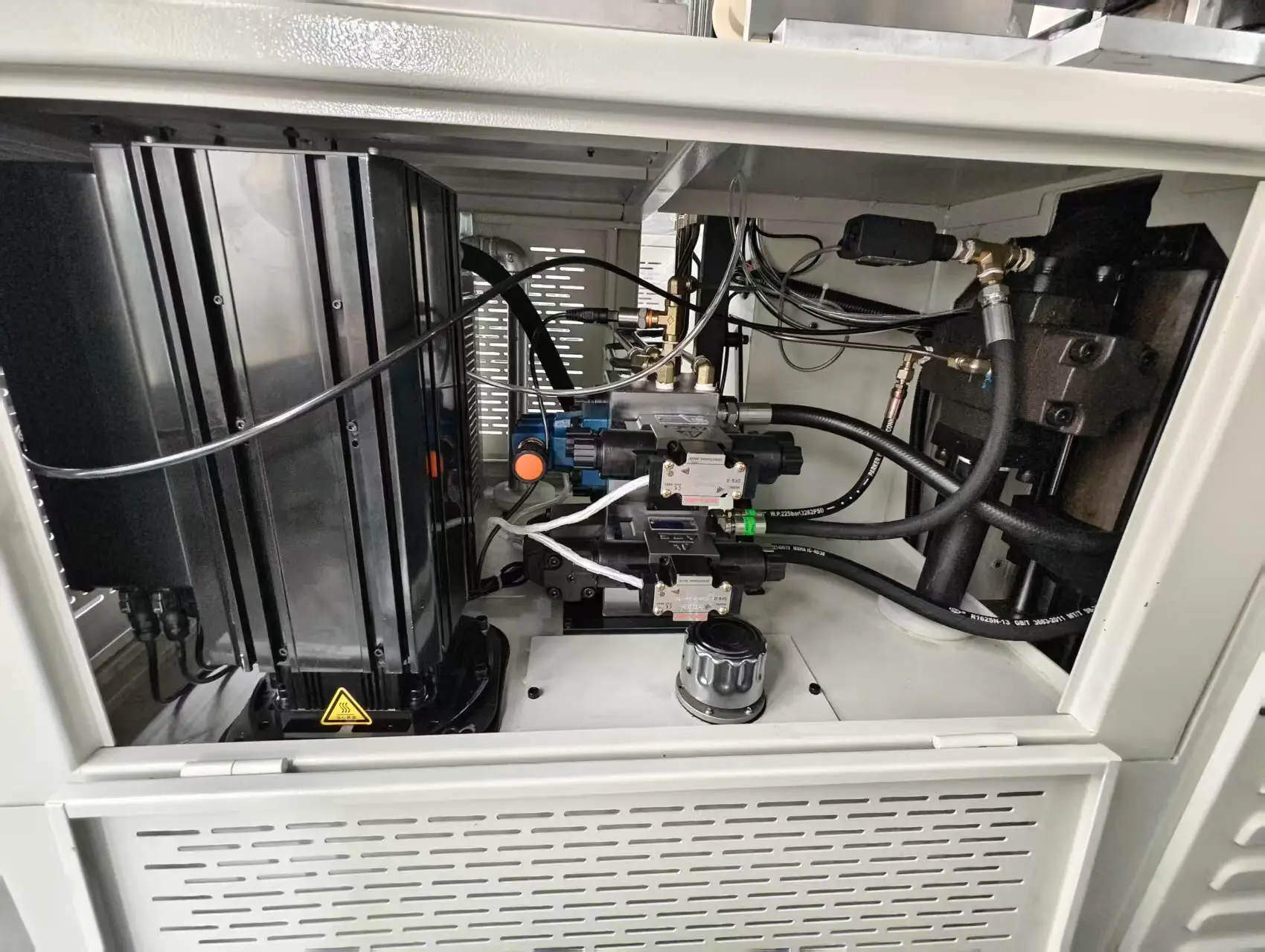

The auto zipper machine features advanced close-end injection molding technology, ensuring precision and efficiency in the production of high-quality zipper components. With its innovative thimble location system, the machine optimizes the injection process, allowing for seamless integration and consistency in manufacturing. Engineered for durability and ease of use, this machine enhances operational productivity while minimizing waste, making it an invaluable asset for any modern production line.

◎ Precision

◎ Efficiency

◎ User-Friendly

Application Scenario

Material Introduction

The Auto Close-End Injection Molding Machine with Thimble Location is constructed using high-quality materials such as durable metal alloys and reinforced plastic components. These materials ensure the machine's longevity and reliability for seamless operation in producing auto zippers. The close-end injection molding machine is designed to withstand the rigors of high-volume production while maintaining precision and accuracy in thimble location.

◎ Durable Steel Construction

◎ Precision Components

◎ Robust Build

FAQ

Company Introduction

With the location in Wenzhou Hongye Precise Machinery Co., Ltd. mainly produces and sells Zipper Machine,Zipper Teeth Making Machine,Zipper Slider Mounting Machine,Zipper Injection Moldin. Through continuous pursuit of excellence, our company hopes to become a well-respected and sustainable global enterprise in the future. In this way, we can create better social and economic benefits and bring more competitive value to employees and customers. Our company's R&D team has rich experience and excellent technical capabilities. With the constant focus on the research of product innovation, they have made major breakthroughs. And it has laid a solid foundation for our sustainable development. With professional service spirit, ZYN Machine always provides customers with reasonable and efficient one-stop solutions.

Hello, thanks for your attention to ZYN Machine! If in need, please feel free to call us or place orders. We are committed to serving you!