ZYN Machine-Precision And Innovation Zipper Machine Manufacturer Over 30 Years.

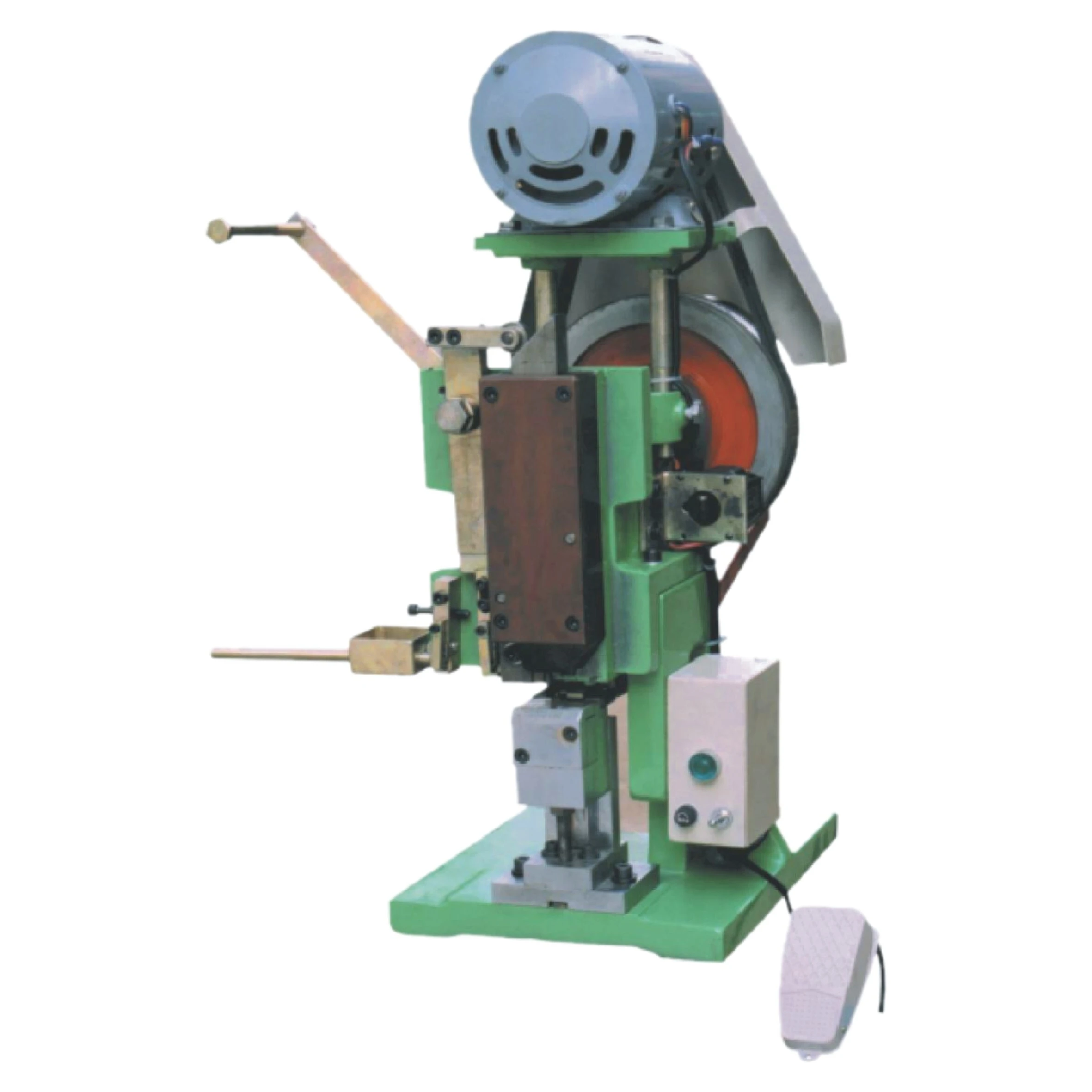

HY-113J/HY-113N Semi-Automatic Bottom Stop Machine(Wire)

The machine fastens metal wire bottom stop.

Semi-auto machine, easy to operate, steady working, high speed.

Suitable for small quantity order.

Efficient, Versatile, Reliable, Precise

The Semi-Auto Bottom Stop Machine (Wire) streamlines your zipper production process, ensuring precise and efficient application of bottom stops with every use. Designed for reliability and ease, this semi-auto zipper machine enhances workflow by reducing manual effort while maintaining high-quality standards in packaging and functionality. Experience improved productivity and consistency in your operations with this essential tool for producing durable zippers in various shapes and styles.

● Efficiency

● Precision

● Durability

● User-Friendly

Product Display

Efficient, Versatile, Reliable, Precision

Efficient, Versatile, User-Friendly, Durable

The Semi-Auto Bottom Stop Machine (Wire) is engineered to enhance efficiency and precision in zipper production, boasting advanced semi-automatic capabilities that streamline operations. With its specialized design, this bottom stop machine ensures consistent application of bottom stops, resulting in high-quality zippers suitable for various textile applications. Its robust structure and user-friendly interface provide operators with ease of use while maintaining durability and reliability in high-volume manufacturing environments.

◎ Efficiency

◎ Precision

◎ Durability

Application Scenario

Material Introduction

The Semi-Auto Bottom Stop Machine (Wire) is engineered with high-quality materials to ensure durability and efficiency in handling zipper applications. Its robust metal frame provides stability during operation, while the precision components are designed to deliver accurate sealing for zippers. This semi-auto zipper machine is further enhanced with user-friendly features, making it an essential tool for streamlining the production process in the garment industry.

◎ High-Grade Steel

◎ Precision Components

◎ Heavy-Duty Frame

FAQ