ZYN Machine-Precision And Innovation Zipper Machine Manufacturer Over 30 Years.

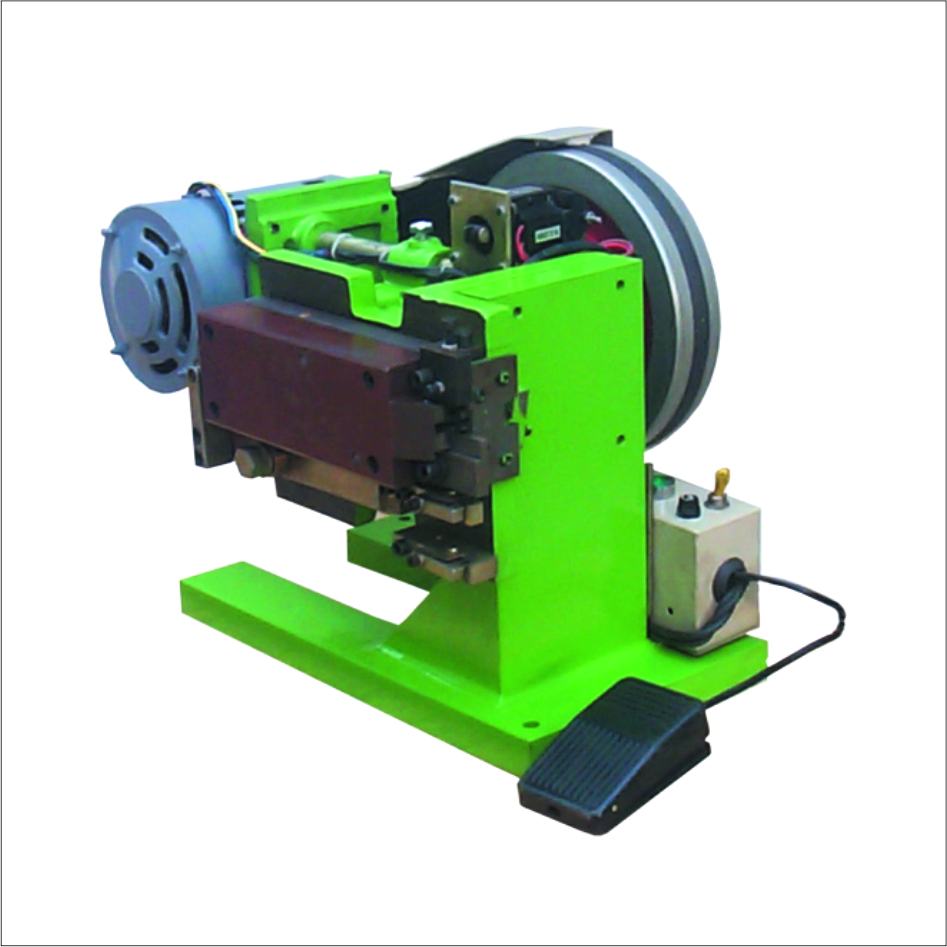

HY-107J Semi-Automatic Metal Zipper Top Stop Machine(Wire)

Apply to sample or small quantity order.

Efficient, Durable, Versatile, Reliable

Experience enhanced efficiency and precision with our semi-auto zipper machine, designed to streamline your production process for metal zippers. With its durable construction and user-friendly design, the metal zipper top stop machine ensures consistent quality and reduces downtime in your operations. Optimize your workflow while achieving reliable results, making it an essential addition to your manufacturing setup.

● Efficiency

● Precision

● Reliability

● Versatility

Product Display

Efficient, Durable, Versatile, Reliable

Efficient Zipper Assembly Solution

The semi-auto metal zipper top stop machine is designed for efficient production of high-quality metal zippers, ensuring precise and consistent application of top stops. Its innovative semi-automatic operation enhances productivity while minimizing labor costs, making it an ideal choice for manufacturers seeking reliable performance in zipper assembly. Built with durable materials and advanced engineering, this machine guarantees longevity and withstands the rigors of industrial environments, while delivering impeccable results.

◎ Precision

◎ Efficiency

◎ Durability

Application Scenario

Material Introduction

The semi-auto metal zipper top stop machine is built with robust materials that ensure durability and reliability during operation. Crafted from high-quality metal components, the machine guarantees consistent performance in producing metal zipper top stops, making it ideal for industrial applications. Its precision-engineered parts contribute to efficient functioning, allowing manufacturers to enhance their production processes seamlessly.

◎ Durable Construction

◎ Precision Engineering

◎ User-Friendly Maintenance

FAQ