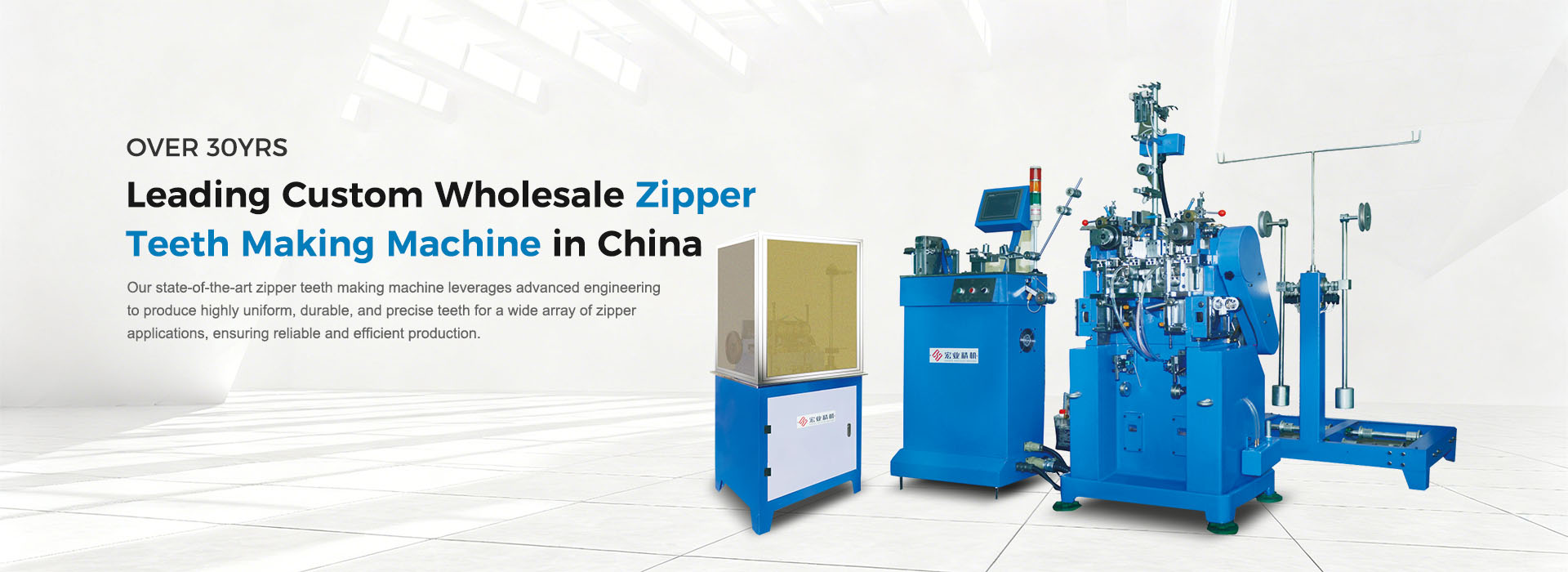

Professional Zipper Teeth Making Machine Manufacturer since 1995-ZYN Machine

Our End-to-End OEM Partnership Process:

• Consult & Co-create: We begin by discussing your vision to define requirements and customization options.

• Design & Engineer: Our experts develop tailored solutions, adapting our designs to your specific OEM needs.

• Prototype & Validate: We create samples for your approval, ensuring the design aligns perfectly with your expectations.

• Test & Assure: Products undergo rigorous checks for functionality, reliability, and compliance.

• Produce & Scale: We manufacture your order with precision, maintaining consistent quality and efficiency.

• Quality Verify: Every product passes a final, thorough inspection to guarantee integrity and performance.

• Pack & Personalize: We customize packaging to reflect your branding and meet logistical needs.

• Deliver & Support: We manage logistics for timely and secure delivery to your destination.

In terms of production, we undergo strict quality inspections from material procurement to parts processing, to product warehousing and delivery.

After three decades of technological innovation and pragmatic dedication, ZYN Machine has established itself as a leading industrial zipper equipment manufacturer integrating R&D, production, sales, and service.

Our comprehensive product range includes zipper cutting machines, sealing machines, gapping machines, slider mounting machines, hole punching machines, and other automated zipper production equipment. We specialize in delivering complete, high-performance production line solutions that rank among the finest in the industry.

Recognized for our expertise and credibility, ZYN Machine has contributed to the drafting and formulation of seven national zipper industry standards and has been honored as the Wenzhou Mechanical Design R&D Center.

Since the company was founded, its products have passed CE certification and it has more than 100 invention and new patents.